Introduction

Choosing the right wood for toys is essential for ensuring durability, safety, and aesthetic appeal. This guide compares hardwood and softwood, helping you make an informed decision.

Characteristics of Hardwood

Common Types: Oak, Maple, Beech, Walnut, Basswood, Birch

Properties:

-

Density and Strength: Hardwoods are generally denser and stronger than softwoods, making them more durable and resistant to wear and tear.

-

Grain and Appearance: Hardwoods often have a tighter grain and more attractive appearance, which is ideal for aesthetically pleasing toys.

-

Weight: They are heavier, which can be a consideration for toy size and usability.

Benefits:

-

Durability: Ideal for toys that will endure rough handling and need to last for generations.

-

Safety: The density makes hardwood less likely to splinter, which is safer for children.

-

Finish: Takes paint and varnish well, resulting in a smooth and polished finish.

Drawbacks:

-

Cost: More expensive due to slower growth rates and higher processing costs.

-

Workability: Harder

Characteristics of Softwood

Common Types: Pinewood , Fir, Spruce, Cedar

Properties:

-

Density and Strength: Softwoods are generally lighter and less dense than hardwoods, making them easier to handle and work with.

-

Grain and Appearance: Softwoods often have a more open grain, which can be less aesthetically pleasing compared to hardwoods.

-

Weight: They are lighter, which can be beneficial for larger toys that need to be easily moved or carried.

Benefits:

-

Cost: Typically less expensive due to faster growth rates and easier processing.

-

Workability: Easier to cut, shape, and join, making them ideal for more intricate designs and quicker production times.

-

Availability: More widely available and sustainably sourced.

Drawbacks:

-

Durability: Less durable and more prone to dents and scratches compared to hardwoods.

-

Safety: More likely to splinter, which can pose a safety risk for children.

-

Finish: May not take paint and varnish as smoothly as hardwoods, resulting in a less polished finish.

Comparing Use in Toy Manufacturing

Durability:

-

Hardwood: Better for toys that need to withstand heavy use and last for years.

-

Softwood: Suitable for toys that are less likely to experience rough handling or for toys designed for younger children.

Safety:

-

Hardwood: Generally safer due to reduced risk of splintering.

-

Softwood: Requires careful finishing to prevent splintering and ensure child safety.

Cost and Availability:

-

Hardwood: More expensive and less readily available in large quantities.

-

Softwood: More cost-effective and widely available, making it a popular choice for mass-produced toys.

Aesthetic and Finish:

-

Hardwood: Preferred for high-end toys that emphasize visual appeal and a smooth finish.

-

Softwood: Works well for toys where intricate design and ease of production are prioritized.

Preferred Woods by Renowned Toy Brands

| Grimms Germany |

Utilizes hardwoods like Alder, Lime, and Basswood. |

| Le Toy Van United Kingdom |

Favors hardwoods, specifically Rubberwood and Basswood. |

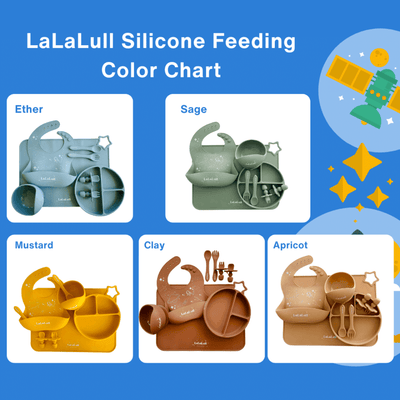

| LaLaLull Australia® |

Chooses hardwood, particularly Basswood & Beechwood, for their toys. |

In conclusion, the choice between hardwood and softwood in toy making hinges on factors such as durability, safety, and cost. A thorough understanding of these materials aids in choosing the most appropriate wood for children's toys, ensuring both safety and enjoyment.