When it comes to selecting Baby feeding sets for our little ones, safety is the top priority for every parent. In the ever-evolving world of baby products, silicone feeding sets have emerged as a popular choice due to their durability, ease of cleaning, and BPA-free material. But what about the safety of printed designs on these sets? Let's dive into the world of printing on silicone feeding sets and explore the innovative methods that ensure both style and safety.

🔍 Exploring the Safety of Printed Silicone Feeding Sets: What Parents Need to Know

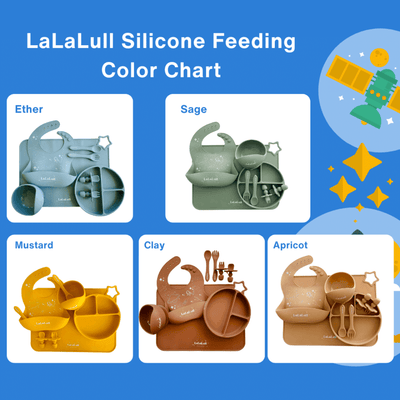

Silicone feeding sets, beloved for their softness and resistance to bacteria, are a staple in many households. However, the question of whether printing on these sets compromises safety is a concern for mindful parents. Rest assured, with advancements in printing technology, it's now possible to adorn these feeding essentials with colorful designs without sacrificing safety.

Method 1: The Vibrancy and Versatility of Screen Printing Logos

🎨 What Is Screen Printing? Screen printing involves applying ink through a mesh screen to create vibrant, detailed designs. This method is favored for its ability to produce bright, lasting colors and intricate patterns.

🛡️ Safety First: When it comes to silicone feeding sets, using non-toxic, baby-safe inks is crucial. Our screen printing process ensures that all materials meet stringent safety standards, making them completely safe for your little one.

Photo Resource: LaLaLull silicone bib

The Science and Safety of Screen Printing on Silicone

The Basics of Screen Printing: This traditional printing method has been refined for modern applications, including the decoration of silicone feeding sets. It involves the transfer of food-grade ink onto the silicone surface through a precisely crafted mesh screen, which can reproduce intricate designs with high fidelity.

Ensuring Durability and Safety: The critical advancement in our screen printing process is the curing of the ink. By subjecting the printed silicone to high temperatures in a specialized oven, we achieve a solidification of the ink that is both durable and resistant to fading. This step is crucial for ensuring that the print will not degrade or leach over time, even with repeated washing and exposure to the harsh conditions of daily use.

Method 2: The Elegance and Durability of Engraving Logos

✨ Why Engraving? Engraving removes a layer of silicone to create a design. This method doesn't add any substances to the feeding set, making it an inherently safe option for embellishing silicone products.

🌿 Eco-Friendly and Lasting: Engraved designs are not only elegant but also permanent. They won't fade or wear off, ensuring the longevity of your feeding sets without compromising their safety or environmental footprint.

Method 3: Precision and Innovation with Laser Carving Logos

🔍 Laser Carving Explained: This technique uses laser technology to precisely carve designs into silicone. It offers unparalleled accuracy and detail, allowing for intricate logos and patterns.

🚫 No Additives: Similar to engraving, laser carving adds no additional materials to the silicone, maintaining the purity and safety of the feeding sets.